For over a century, the industrial business model has been straightforward: build a high-quality machine, sell it, and then offer a separate service contract for repairs. But a powerful shift is underway, driven by data and connectivity. This is the era of servitization, where manufacturers are moving from selling products to selling outcomes.

Instead of buying a compressor, your customer buys a guaranteed supply of compressed air. Instead of buying a turbine, they buy 99.9% energy uptime.

This “Product-as-a-Service” (PaaS) model is the next frontier of industrial revenue, and it is only made possible through the intelligence provided by the Industrial Internet of Things (IIoT).

Why the Shift to Servitization is Happening Now

The model isn’t new, but its viability is. Previously, offering a guaranteed uptime contract was a massive financial gamble. A single unexpected failure could wipe out the profit margin for an entire year. Without real-time visibility, manufacturers were flying blind.

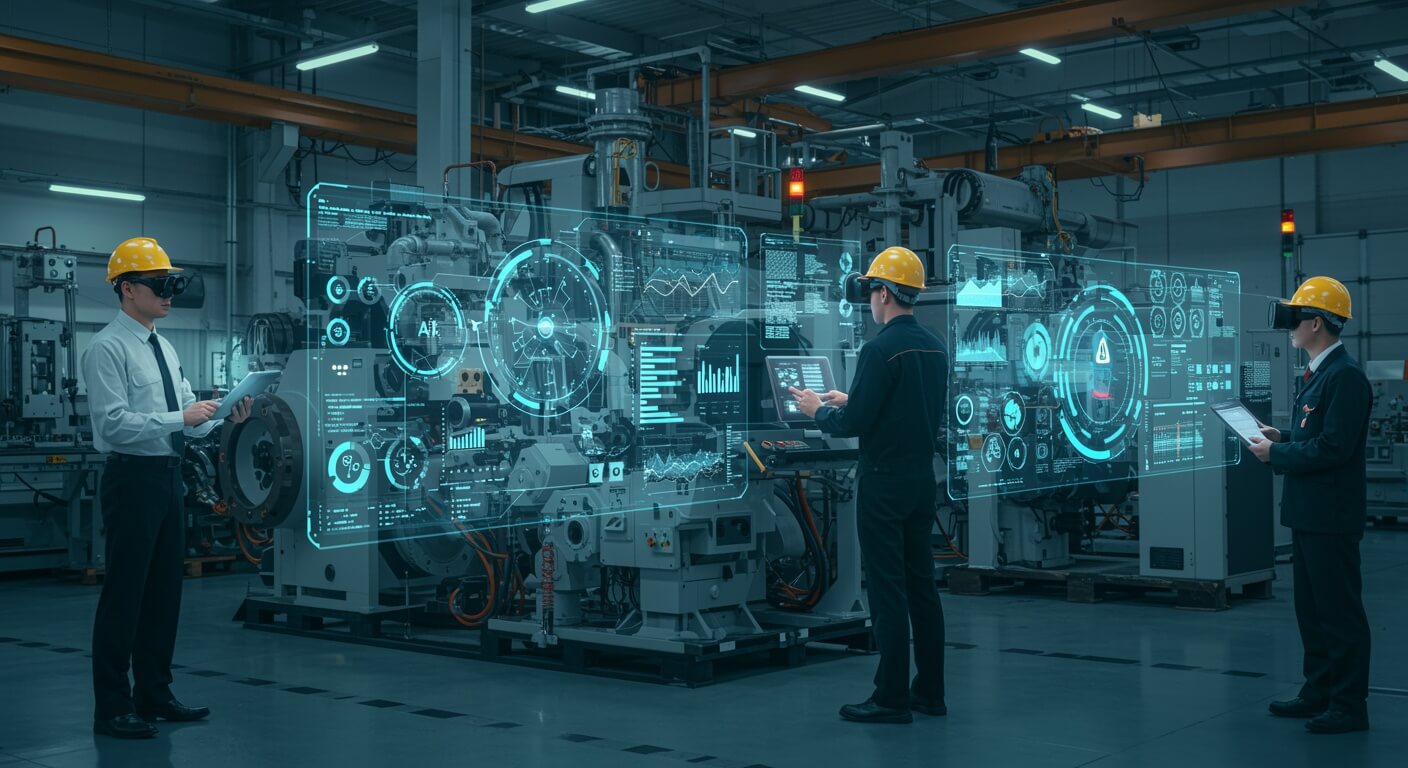

Today, this has changed completely. Technology platforms like those from Aswartha Group de-risk the servitization model by providing the three essential pillars of an outcome-based business:

1. Pillar One: Total Visibility with Condition Monitoring

To guarantee an outcome, you must first have complete, 24/7 visibility into the health of your asset operating at the customer’s site. Our ACME (Asset Condition Monitoring Experts) solutions provide this foundation. By deploying advanced sensors that track vibration, temperature, and other critical parameters, you are no longer guessing about your machine’s health—you know it in real-time. This live data stream is your eyes and ears on the ground.

2. Pillar Two: Predictive Insight with AI Analytics

Visibility is not enough; you need foresight. The data from your deployed assets is fed into our ALMAS (AI-Driven Lifecycle Machine Analytics) engine. This platform acts as your risk-mitigation engine.

ALMAS analyzes the data to predict component wear and forecast potential failures weeks in advance. This transforms your service model from reactive to proactive. You no longer wait for the customer to call with a problem. Instead, you can schedule maintenance during their planned downtime, dispatching a technician with the correct parts before the failure ever occurs. This is how you profitably deliver on an uptime guarantee.

3. Pillar Three: A Unified Platform for Smart Decisions

Managing a fleet of deployed assets requires a single source of truth. Our AAMS (Advanced Asset Management Systems) provides a centralized dashboard that visualizes the health, performance, and maintenance needs of every machine in your PaaS portfolio.

This allows you to manage your service logistics with incredible efficiency. You can optimize technician schedules, manage spare parts inventory intelligently, and provide your customers with transparent, data-driven reports on the value you are delivering.

The Future is Selling Outcomes, Not Just Products

The servitization model offers a powerful competitive advantage. It creates recurring, predictable revenue streams, fosters deeper customer loyalty, and transforms your business from a simple equipment vendor into an indispensable operational partner.

The technology to make this shift is no longer a futuristic concept; it’s a proven reality. Aswartha Group provides the end-to-end IIoT backbone that gives you the confidence to stop selling machines and start selling what your customers truly value: guaranteed performance.